Wireless Petroleum Level Measurement Using Ultrasonic Digital Sensor

Wireless Petroleum Level Measurement Using Ultrasonic Digital Sensor is an advanced industrial automation solution designed by Project Center Kerala to provide accurate and real-time monitoring of liquid levels in petroleum tanks and reservoirs. This innovative system addresses the critical challenges faced in the petroleum industry, where precise inventory management and leak detection can prevent significant financial losses and environmental hazards.

Wireless Petroleum Level Measurement Using Ultrasonic Digital Sensor is an advanced industrial automation solution designed by Project Center Kerala to provide accurate and real-time monitoring of liquid levels in petroleum tanks and reservoirs. This innovative system addresses the critical challenges faced in the petroleum industry, where precise inventory management and leak detection can prevent significant financial losses and environmental hazards.

The Problem: Traditional methods of measuring petroleum levels often involve manual dipstick readings or mechanical float systems that are prone to error, require frequent maintenance, and pose safety risks to personnel. With increasing regulatory requirements and operational efficiency demands, petroleum facilities need more reliable monitoring solutions.

Our Solution: Our wireless ultrasonic system offers non-contact measurement technology that eliminates the limitations of conventional methods. By using sound waves that bounce off the liquid surface, the system calculates the exact level with millimeter precision, regardless of liquid properties or environmental conditions.

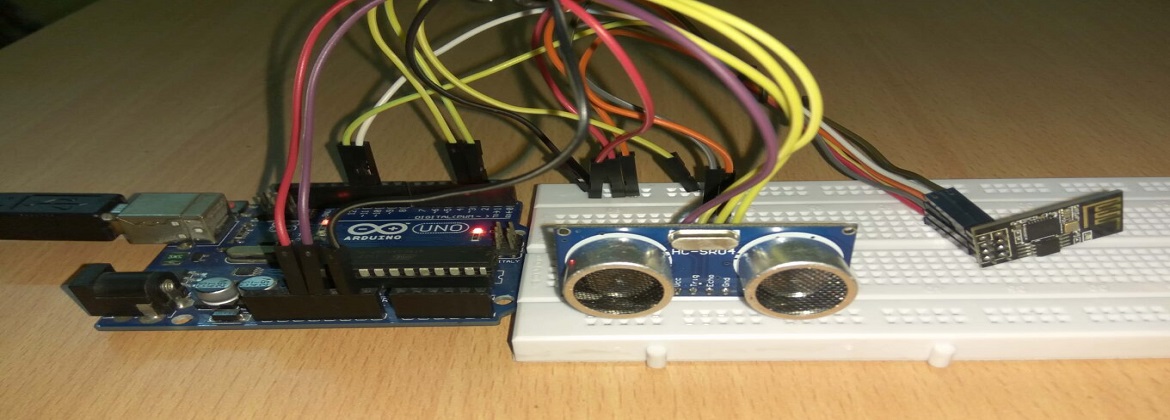

How It Works: The system architecture consists of three integrated stages:

- Sensing Circuit: Premium ultrasonic digital sensors mounted on the tank top emit high-frequency sound waves and measure the time taken for echoes to return after bouncing off the petroleum surface.

- Wireless Communication: The measured data is encoded and transmitted via secure RF communication protocol to a receiving station that can be positioned up to 100 meters away (line of sight).

- Control & Display System: A microcontroller processes the received signals, converts them to volume measurements based on tank geometry, and displays real-time levels on an LCD interface with customizable alert thresholds.

Technical Specifications:

- Measurement Range: 5cm to 4.5m (customizable for larger tanks)

- Accuracy: ±0.25% of measured distance

- Resolution: 1mm

- Update Rate: Configurable from 1 second to 60 minutes

- Power Supply: 12V DC (with battery backup option)

- Wireless Range: Up to 100m (line of sight)

- Operating Temperature: -20°C to +80°C

- Protection Rating: IP65 (optional IP68 for sensor unit)

Key Components: Our system utilizes industrial-grade components including waterproof ultrasonic digital sensors, encoder/decoder ICs for secure data transmission, high-reliability RF transmitter-receiver pairs, ARM-based microcontroller for signal processing, and weatherproof enclosures for outdoor installations.

Applications: This technology has been successfully implemented across:

- Petroleum Distribution Terminals: For inventory management and logistics optimization

- Oil Refineries: For process control and safety monitoring

- Fuel Stations: For automated inventory tracking and leak detection

- Chemical Plants: For hazardous liquid level monitoring

- Remote Storage Facilities: For unmanned monitoring via IoT integration

- Mobile Tankers: For transportation safety and volume verification

Business Benefits:

- Cost Reduction: Eliminates manual readings, reduces human error, and prevents overfill incidents

- Enhanced Safety: Removes the need for workers to climb tanks or be exposed to hazardous fumes

- Environmental Protection: Early leak detection capabilities help prevent ground contamination

- Operational Efficiency: Real-time inventory data enables just-in-time delivery and optimal stock management

- Regulatory Compliance: Helps meet EPA and other regulatory requirements for petroleum storage monitoring

- Data Integration: Optional cloud connectivity for enterprise resource planning systems

Implementation Process: Project Center Kerala provides end-to-end services including site assessment, system customization, installation, calibration, staff training, and maintenance support. Our typical project timeline ranges from 2-4 weeks depending on site complexity and specific requirements.

Case Study: A recent implementation at a major petroleum distribution terminal in Kerala resulted in 15% inventory management cost reduction and eliminated three safety incidents that were common with their previous manual measurement system.

For more details about this technology or to schedule a consultation for your specific petroleum level measurement needs, contact our engineering team at Project Center Kerala today.

Hours

Monday - Saturday: 9:00 AM - 5:00 PM

Sunday: Not Working

Location

PJ5190, South Road, Mudavanmugal, Poojappura,

Trivandrum, Kerala 695012

Book Now

+91 9633118080